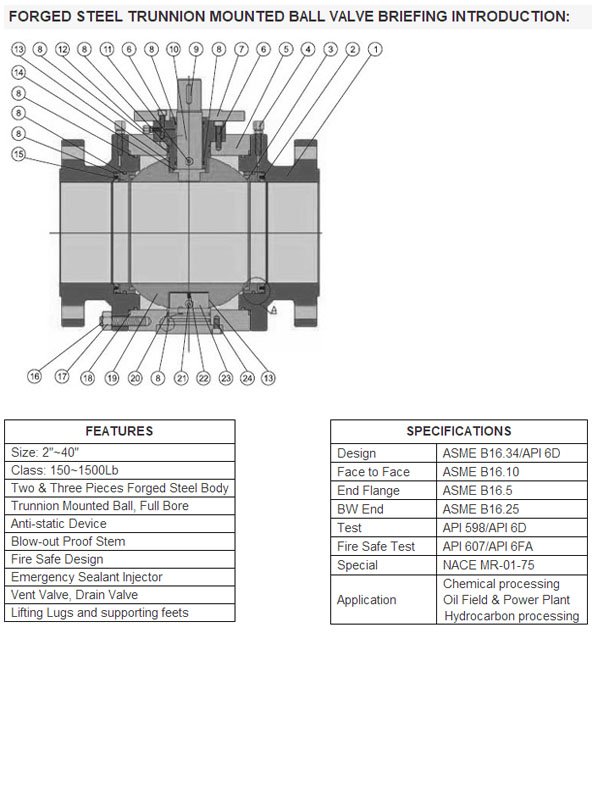

Three-piece Body Trunnion-Mounted Ball Valve

Key Structural Features

✅ Trunnion-Mounted Fixed Ball: API 608/6D-compliant design for zero leakage in oil, gas, and chemical pipelines (Class 150-1500).

✅ Triple-Component Body: Bolted or welded cover options for easy maintenance (ANSI B16.34).

✅ Blowout-Proof Stem: Anti-static design with API 607/6FA fire-safe certification.

✅ Dual Sealing System:

Dual-Piston Effect Seats: Self-relieving capability with injection/drain ports for fugitive emission control.

Full/Reduced Bore: ANSI B16.10 face-to-face dimensions for piggable or high-flow applications.

✅ High-Strength Materials:

ASTM A105N (carbon steel) for standard hydrocarbon service.

A182 F304/F316/L (stainless steel) for corrosive/acidic media.

Certifications & Testing

Design: API 6D, BS 5351, ANSI B16.5/B16.25 flanged/butt-weld ends.

Pressure Testing: API 598/API 6D hydro/pneumatic tests.

Fire Safety: API 607/6FA compliant graphite seals and metal-to-metal backup.